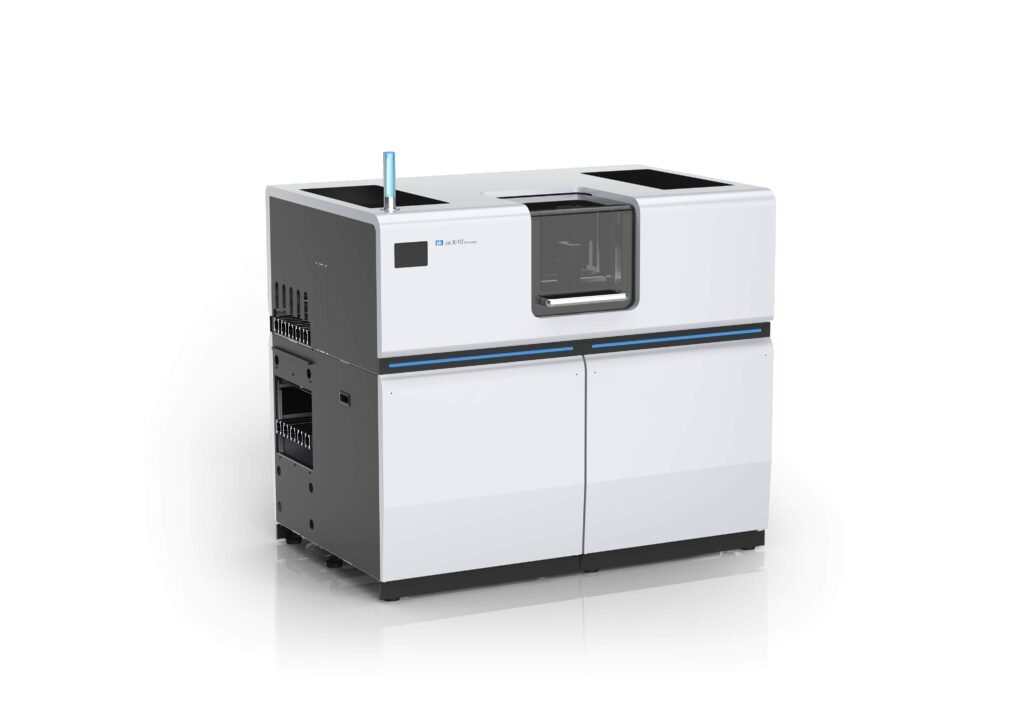

IDS-CLAS X-10

The IDS-CLAS X-10 delivers high-speed sample processing, capable of managing up to 4,000 tubes per hour.

Ensuring continuous operation and long-term reliability, the IDS-CLAS X-10 is engineered to maintain peak performance even under continuous high-volume demands and being able to withstand system overloading without compromising efficiency.

Every sample that enters the laboratory automation system is loaded onto RFID-tagged sample carriers, allowing laboratories to efficiently monitor, retrieve, and review samples at any stage of the workflow.

The connecting transport track of IDS-CLAS X-10 has a double-decker conveyor system, which enables laboratories to automatically processes samples requiring re-runs.

Using an integrated elevator system, samples move to the lower tier for re-routing and return to the upper tier for re-testing—all without increasing the system’s footprint or extending turnaround time.

* The IDS-CLAS X-10 Series is currently in development phase. Features and specifications are subject to change.

Ascending Sample Carrier Elevator

Transports sample carriers from lower-tier to the upper-tier .

Bulk Loader

Designed to handle high volumes of incoming samples, the bulk loader accommodates multiple samples of different tube sizes to be loaded/poured through the top opening as needed.

- Loading capacity up to 800 tubes

- Throughput up to 4000 tubes/hour

- The track supports redundant modules for increased sample volume.

Inlet

Links information of samples arriving from the Bulk Loader & Inlet via RFID tag on the sample carrier. Manages multiple tube sizes.

Features

- 8 x IDS 50-tube racks

- Loading capacity: 400 samples

- Transfers sample from rack to track system via individual sample carriers

- The track supports redundant modules for increased sample volume.

Decapper Module

Caps of sample tubes are removed by a rotational mechanism, which gets directly discarded into the internal bio-hazard container. Minimizing aerosol exposure and ensuring lab biosafety.

- Rubber stopper

- Plastic stoppers

- Twist/screw caps

The track supports redundant modules for increased sample volume.

High-Speed Merging Lane

Merges incoming samples from Bulk Loader,Inlet and Re-run (from bottom track).

Equipped with ascending elevator mechanism to return rerun samples back to the upper main lane.

High-Speed Sorting Lane

Samples are sorted into multiple lanes based on the sample information received.

Sorts and routes samples based on priority, discipline, centrifugation or/and direct to analyzer(s) or storage.

Analyzer Connection(s)

IDS-CLAS X-10 support analyzer connections on both sides of the track system, significantly reducing sample travel time to the analyzers. The track supports redundant modules.

Rack or Tube-builder Connections

IDS can develop appropriate automated transfer arms designed to unload samples from sample tube carriers and place them into your laboratory analyzer racks.

Point-in-Space (Direct Track Sampling) Connections

For analyzers that are capable of direct-track sampling from primary tubes or aliquots while they remain on IDS sample transportation track.

IDS is able to manufacture direct track sampling connections that fits and facilitates efficient sample transfer depending on your laboratory analyzers type/make.

- The track supports redundant modules for increased sample volume

Recapper Module

Placing plastic rubber caps on primary sample tubes and secondary tubes before routing them to the Storage Module. Ensures secure sealing, preventing contamination and preserving sample integrity during storage and transport.

Minimizing operator contact for improved safety

- The track supports redundant modules for increased sample volume

Outlet Module

Removes samples from Automation Line and loads them into outlet rack for further sorting or archiving. Automated sample retrieval from outlet for additional testing or re-runs.

The rack sorting configuration can be categorized to allow laboratories organize samples based on specific their needs.

- 8 x IDS 50-tube racks

- Loading capacity: 400 samples

- Throughput up to 1000 tubes/hour

- Track supports redundant modules

Higher Throughput Model is Available

- Additional mechanical arm can be added to expedite unloading throughput compared to a single arm outlet.

- Throughput: Up to 2000 tubes/hr

10K Sample Vault

High capacity and high-density storage module that stores up to 10080 (10K) sample tubes.

Automated sample retrieval for additional testing or re-runs. Streamlining sample traceability and minimizing manual handling.

- Track supports redundant modules

- Available in ambient or refrigerated models

- Temperature settings: 2 to 10°C

- Throughput : 1200 samples/hour

- Optional automated sample disposal available

Descending Elevator

Archived or re-run samples from storage together with other empty sample carriers are transported to the lower-tier and sent to the respective destination.

The TLA System includes but also is not limited to the following modules seen above which are all connected via IDS connection track.

The TLA System includes but also is not limited to the following modules seen below which are all connected via IDS connection track.

* The IDS-CLAS X-10 Series is currently in the development phase. Feature, specifications and throughput capacity are subject to change.

Bulk Loader

Multiple samples of different tube sizes can be loaded/poured through the top opening as needed.

Continuous loading capacity with up to 800 tubes. Throughput: 4000 tubes/hour

Sorts the following tube sizes :

- 13 x 75 mm

- 13 x 100 mm

- 16 x 75 mm

- 16 x 100 mm

Inlet

Links information of samples arriving from the Bulk Loader & Inlet via RFID tag on the sample carrier

- Samples are picked up from IDS 50-tube racks and placed into individual sample carriers on the transport line.

- Loading capacity: 400 samples (8 x IDS 50-tube racks)

- 1 of the 8 racks can be configured for Error or STAT Samples

Merging Lane

Sorting Lane

Outlet

Completed samples or samples that require technician’s attention gets unloaded from tube carriers and placed into outlet racks.

Loading capacity: 400 samples (8 x IDS 50-tube racks)

A version with an additional arm expedites unloading throughput up to 2000 tubes/h compared to a single arm outlet (1000tubes/h)

Outlet rack sorting configuration can be customized. Allowing laboratories to organize samples based on their operational needs.

- Completed Samples

- Re-run Samples

- Error Samples

- Sorting Area

10K Sample Storage

Stores up to 10080 sample tubes, the samples are unloaded from carriers, 12 samples at a time and systematically placed into storage racks.

Samples can be automatically retrieved for re-runs and add-ons

For more details on our module specifications, reach out to our sales representatives by clicking the button above.

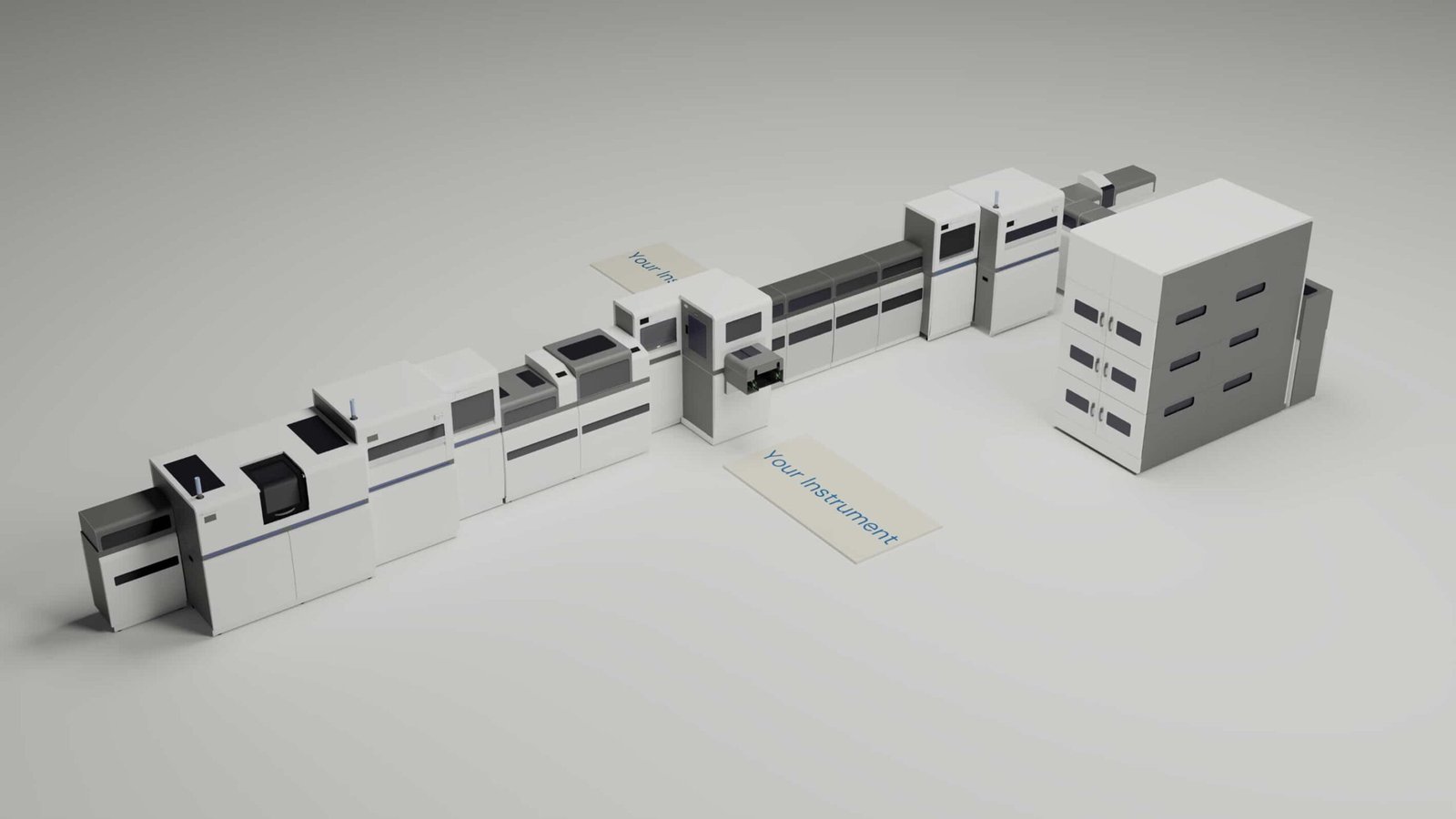

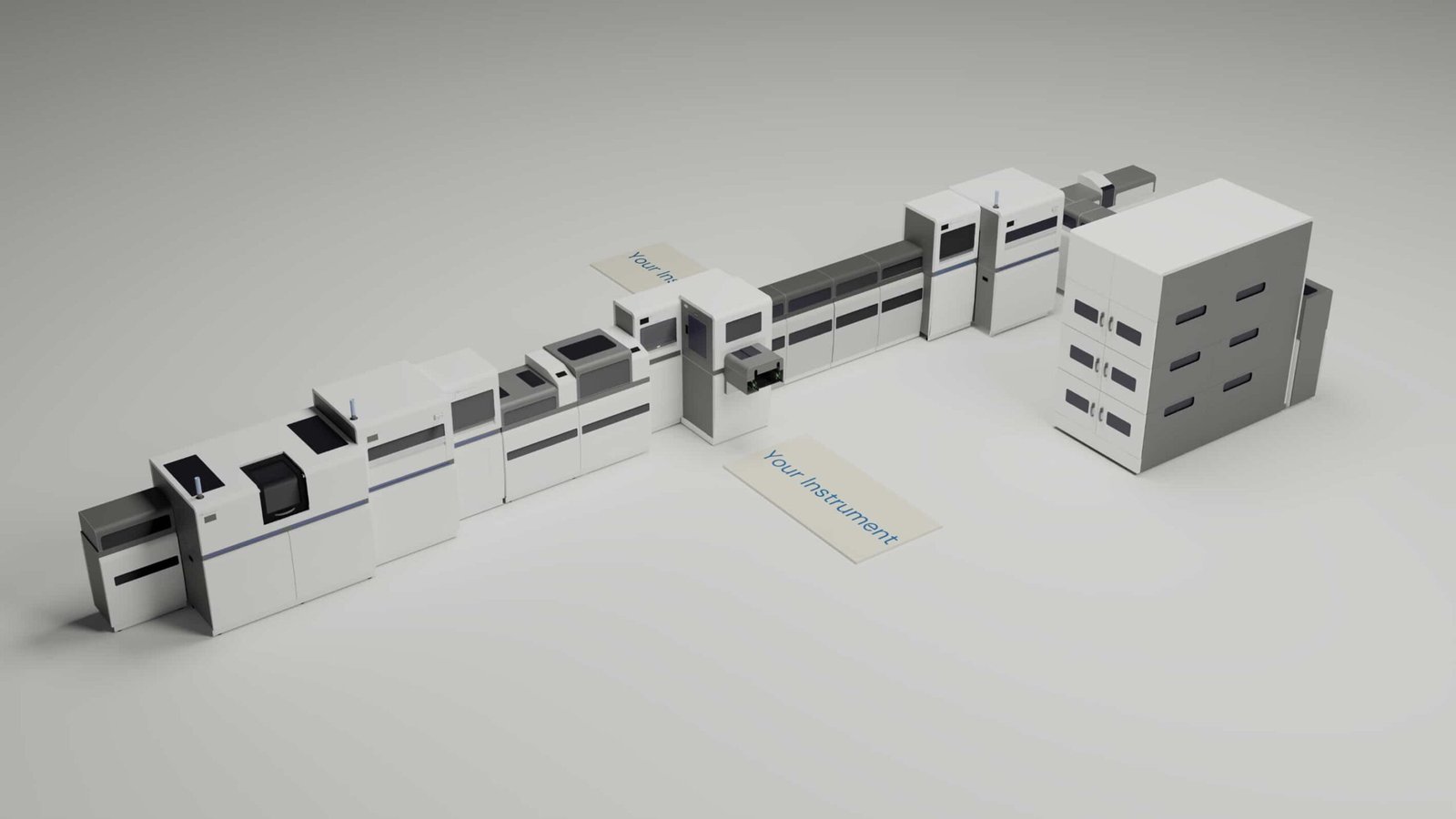

Open Automation Solutions

As an automation system IDS solutions allow laboratories to select the most appropriate interfaces and configurations specific to their workflow needs.

IDS modular track configurations (I, T, H, and L) maximizes space utilization and minimizes sample transit time (TAT), allowing for greater throughput and efficiency.

** Multiple Analyzers across disciplines and various vendors can be configured to the system

- Open to multiple analyzers across disciplines such as chemistry, immunoassay, hematology, and coagulation.

- IDS TLA solutions have integrated with over 40 IVD manufacturers and 100+ analyzer models worldwide, delivering a cohesive automation solution that empowers laboratories to achieve peak operational performance while adapting to evolving healthcare demands.

Find out how IDS TLA Solutions can add flexibility to your Lab

We leverage the power of collaboration to deliver high-value solutions to our end-users. By combining our expertise with that of our partners, we offer a diverse range of options to meet the stringent needs of laboratories.

Are you ready to explore?